Cockpit

Intro

The temptation to try and imitate Nick Schade's (and other) style finally

won, and the initial opening I cut was modified to receive a hybrid

invention of mine, somewhat resembling Nick's technique. I'd suggest

just cutting the form below from the deck, instead of trying my

complicated way. I had no choice: I had already cut the larger hole.

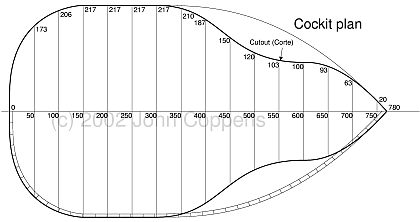

NOTE: Clicking on the image will take you to a high resolution (300 dpi)

image of the cockpit, ready to print. It's better to save and print it.

On a browser it will look huge (> 3000 pixels wide!). Even then, this

drawing is scaled. Use the measures to draw it to size on another paper.

The exact location of the cockpit is a bit difficult. The original (Nick's)

design indicates 2.42 metres from the front. I have the impression that

'my' design is a little longer and could justify moving it a few cm to

the front (say at 2.38 m). Here's the original location:

To follow what happened then, check below.

Photos

|

This shows nicely the form of the plywood added to modify the original

opening.

|

|

The form received its name from its similarity to a keyhole. It provides

for knee support while paddling, and the large opening facilitates

entering/exiting. |

|

I used adhesive paper, marked the outer line to follow. Then I cut 120

5 cm long pieces of wood, about 6 mm thick, 19 mm wide.

|

|

Using fair amounts of patience, sandpaper, and handplaning, I adapted

each piece of wood to the inclination. Each one is fixed with hot glue

to the deck, and using carpenter's glue to each other. |

|

To adapt the form, where the strips are above the deck, mark the correct

inclination...

|

|

... then cut it and glue it on. Note that, while most are glued to the

deck from the inside, in the knee support area, they are just 'sitting' on

the deck. |

|

And a good while later... No too bad, isn't it?

|

|

A side look at the masterwork... |

|

Ready! Of course, the last ones but be adapted in width to fill correctly

the last remaining space.

|

|

After the glue dried, I used a handsaw, with its blade turned 90 degrees,

to cut the border evenly. I cut 17 mm above the deck. Though I guessed this

value, it seems well inside the margins I found later in the books. Below

deck, sand the border to get ir flush with the deck. |

|

Next the upper border. As a result of the hybrid inlay I invented, the

border is a bit more complicated and consists of two different

inclinations. This border uses 4 pieces of plywood.

|

|

The aft section is easiest: it's just parallel with the deck. The picture

shows the glued border (It's too large. I planned to cut it later). |

|

The front part is more complicated, as it follow the hollow section inlaid

in the opening.

|

|

This is the union between both sections. The tape keeps the point aligned. |

|

Everybody must help to keep the pressure! 20 litres keep the strip down.

|

|

Glueing alone is not enough for all the forces this border will receive.

I prepared a strip of fiberglass, with fibers removed to leave only enough

to cover the vertical part. |

|

The strip in place...

|

|

... and now saturated with epoxy. I should have filleted first - now I

know! |

|

Here's the strip completely installed, and the border ready to receive a

first coat of epoxy.

|

|

(c) John Coppens ON6JC/LW3HAZ |

mail |